Summary

At the beginning of March we received an inquiry from the metropolitan area of Stuttgart.

The customer is currently in the process of implementing a new paint shop. Due to the good cooperation in other trades in the past (body work and assembly) we were asked to support the realization of the conveyor technology. Here is an insight into our approach to this topic.

Content:

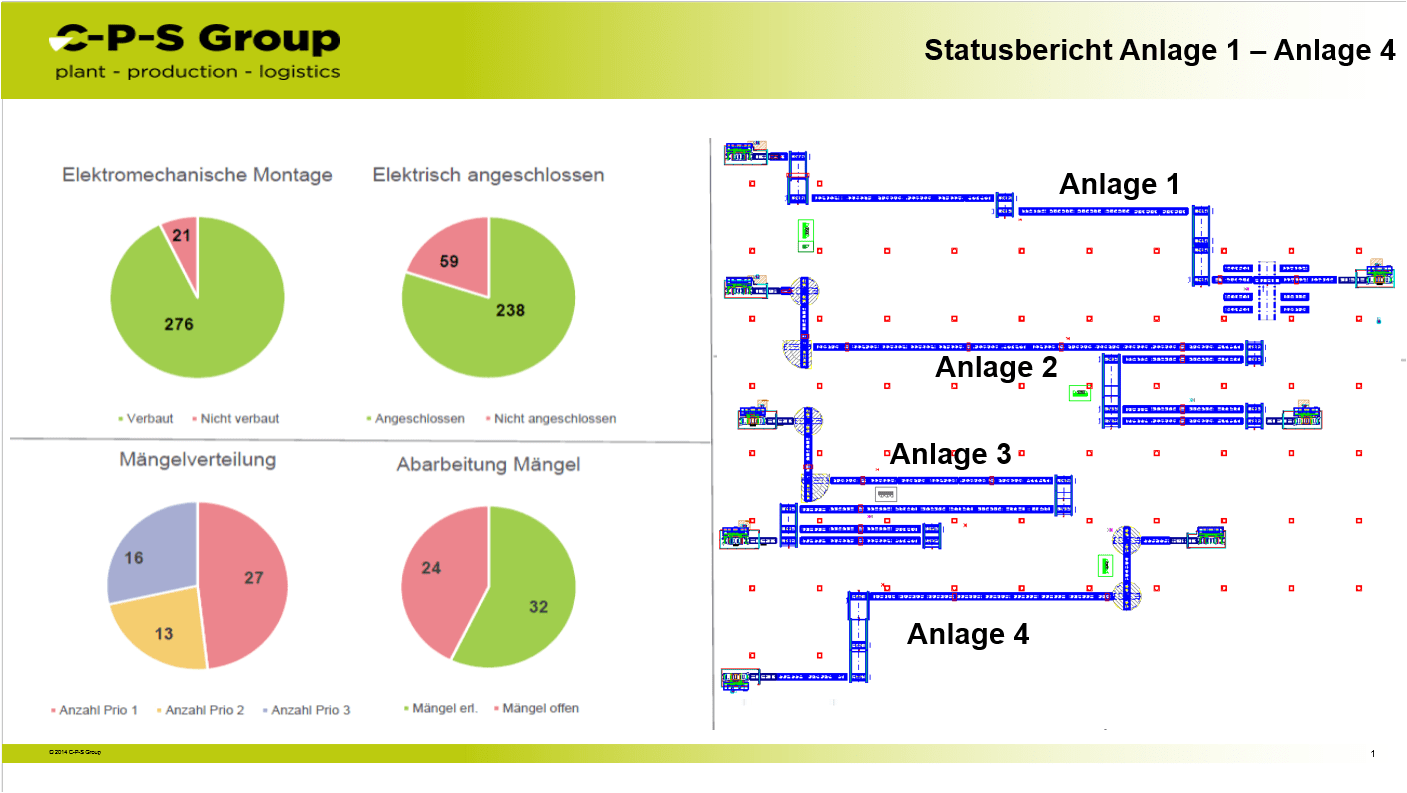

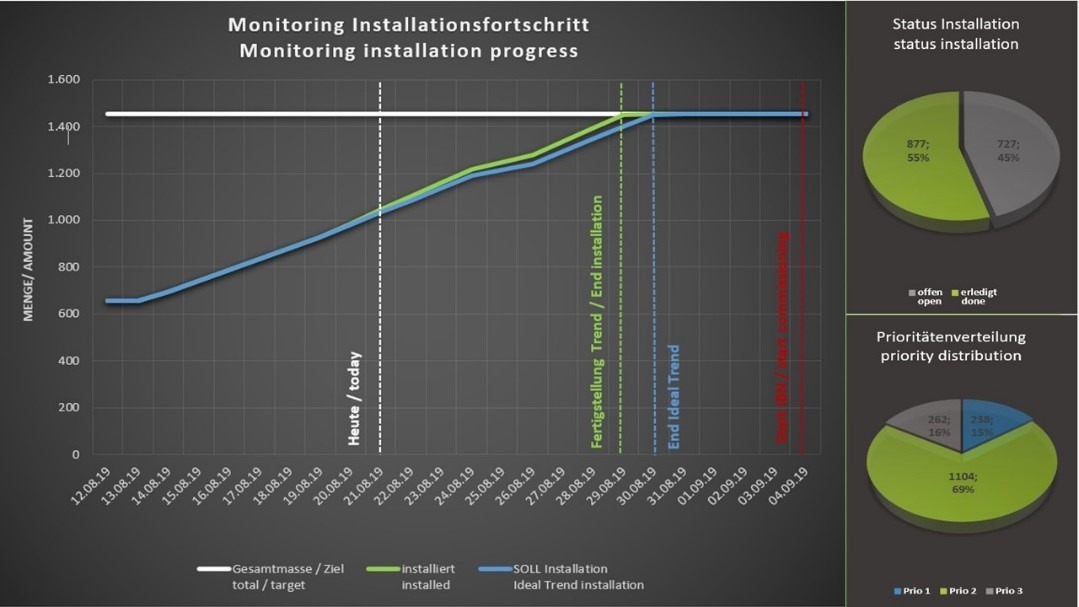

The main tasks include the tracking of the installation and installation progress as well as the detection and follow-up of defects.

In order to achieve better transparency, a separate documentation with „automatic“ status generation was set up in the course of the project initialization phase and documents like e.g. Layouts, schedules and schedules of the supplier adapted to this documentation.

Due to the daily on-site comparison, it is possible for us and the customer at any time to have a live Status of the progress, the defects and their processing, as well as the use of the assembly staff map. Furthermore, we can react to deadline shifts so early and Take countermeasures.

Our clients have complex projects with complex responsibilities and interfaces. The C-P-S Group is not only known for its high level of expertise, but also for the methodical approach appreciated in the projects. Every project needs individual KPIs Emphasis on different needs. Missing transparency often weighs worse than that Shifting of milestones. Therefore, at the beginning of each project, the definition of Project key figures, escalation levels and rule communications, the basis of our cooperation with the customers.

The success of our support has been quickly communicated. Therefore, we are allowed on one look forward to another project in a paint shop in Leipzig.

Mustafa Ünlüsoy

CoC-Leads Installation Planning & Industrial Automation and Conveyor Technology Planning (ETF)

Mob. DE: +49 (0) 151 15061902

Mail: mustafa.uenluesoy@c-p-s.de

About the author:

Mustafa Ünlüsoy has been the CoC Director responsible for the C-P-S equipment technology since 2015.

He can look back on a wealth of experience of around 15 years in the automotive industry. The focus is clearly in the field of materials handling.

Here he was able to successfully carry out a large number of (large) projects with large OEMs.

Already in his first projects, he was able to extend his area of responsibility from original subtasks such as layout planning or concept planning to the responsibility of sub-works such as mechanics or realization support.

The next step in the career followed then the assumption and responsibility of own overall projects with own coworkers and the step to the team leader.

After successful development of the team as well as the growing projects and the customer environment in the area of the equipment technology the next step followed to the CoC leader.

In addition to the technical know-how, social components and sales activities are also in demand here.

In addition to the professional responsibility and further development of the CoC with approximately 40 employees, the employee development and the customer care is an essential part of the work as a CoC leader.

C-P-S Group:

The C-P-S Group is an independent, owner-managed medium-sized company with approximately 180 employees. Since 1982, the C-P-S Group has been a partner in the conceptual planning and realization of production plants and logistical processes in factories. Through a clear focus on this technical advice and service, the C-P-S Group has built up expertise and method know-how that its customers appreciate, also in the context of increased outsourcing of projects. The customers of the C-P-S Group are increasingly coming from the automotive industry and plant construction, but also architectural firms and medium-sized mechanical engineering.